Wholesale Price Enthalpy Air To Air Counterflow Heat Exchanger - ERD Cross&Counter Flow Heat Exchanger – AIR-ERV

Wholesale Price Enthalpy Air To Air Counterflow Heat Exchanger - ERD Cross&Counter Flow Heat Exchanger – AIR-ERV Detail:

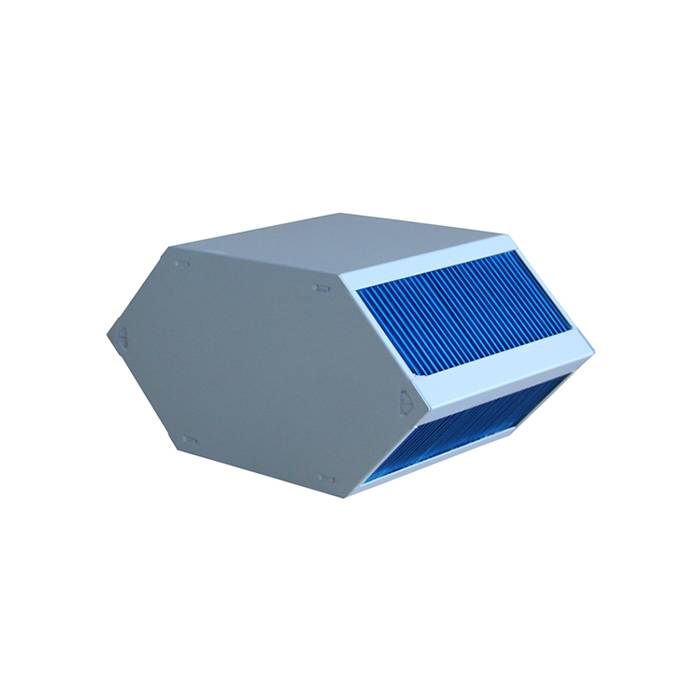

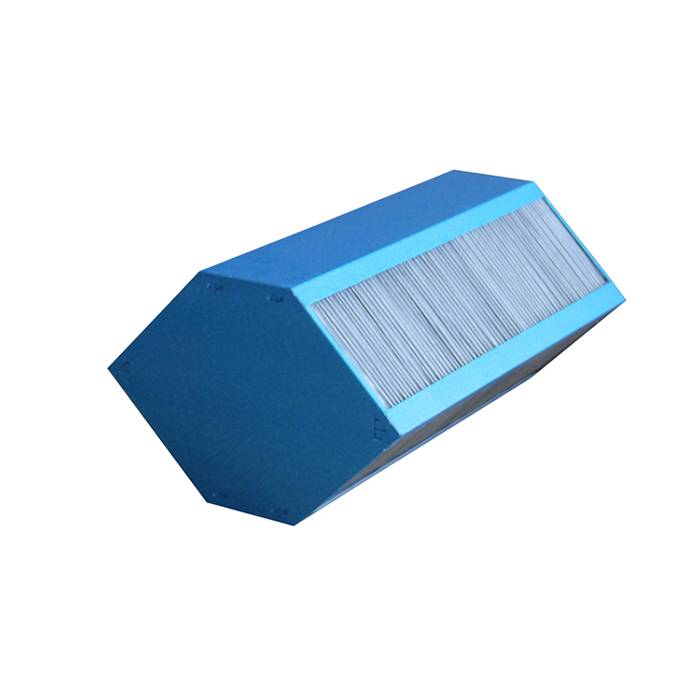

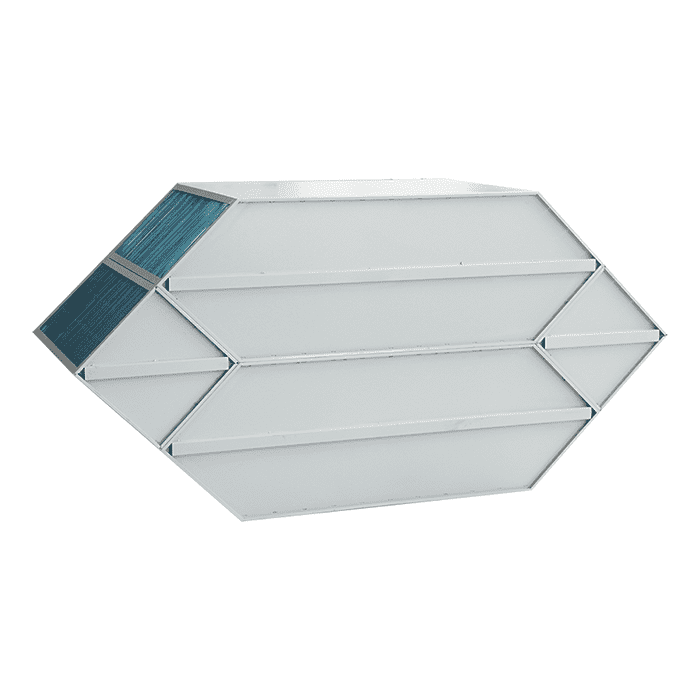

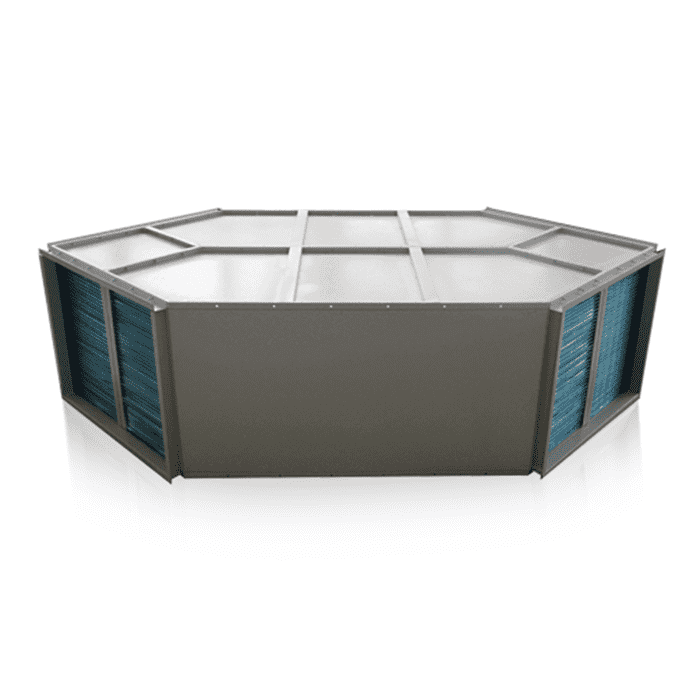

ERD Cross&Counter Flow Heat exchanger Core

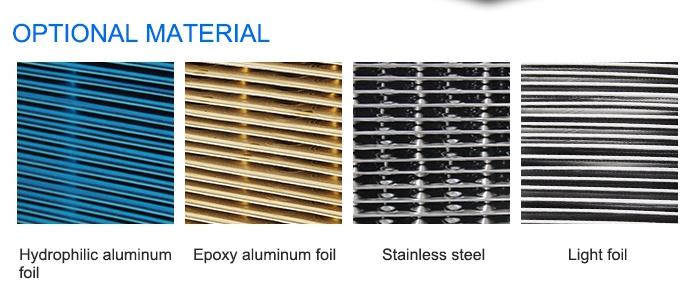

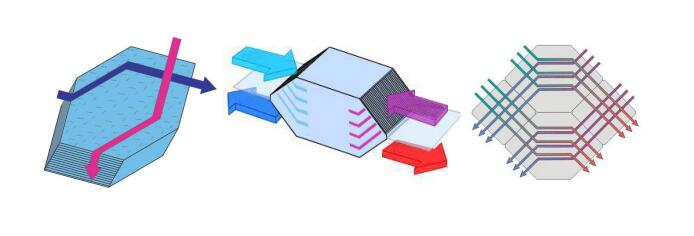

Cross & counter flow heat exchanger core is made of antiseptic hydrophilic/aluminum foil and galvanized sheet cover.A part of air is cross flow, and the other is counter flow, combined the working methods both cross flow and counter flow heat exchanger core, achieve more higher heat efficiency.

It is usually being used for recovering energy at residential household, commercial and industrial ventilation systems.

Feature:

1.Adopt antiseptic hydrophilic aluminium, resistant to corrosion, with long service life.

2.Module and compact structure, no use of rivets or screws.

3.No running components, low maintenance cost.

4.Suitable for washing with water or neutral detergent.

5. Extremely high strength and pressure related stability.

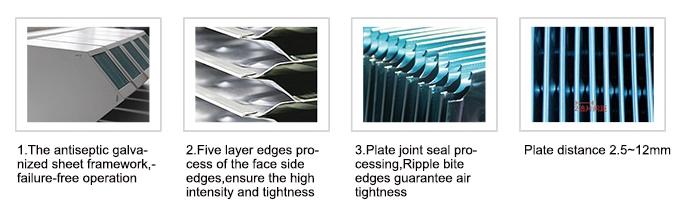

Production Technology:

1.The surface of heat exchanger core was processed with heat transfer enhancement techniques, increased the 10% heat transfer area.

2.Convex and concave air channel, ensure the strength and tightness of heat exchanger core, could bear high pressure.

3.Counter air channel, double folding process of the face side edges, which is equal to 5 times material thickness, ensure the high intensity and tightness.

4. All joints are airproofed by airproof glue, ensured that the heat exchanger core has excellent air tightness.

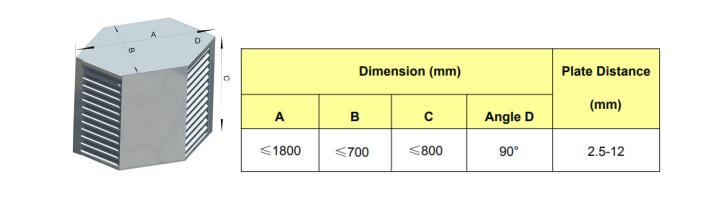

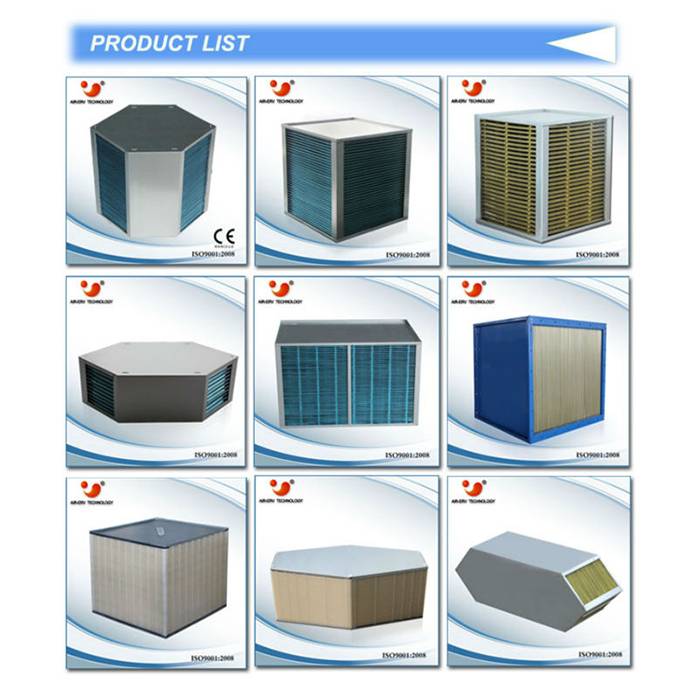

Model Range:

Application:

The cross flow and counter flow heat exchanger core is the major part of heat recovery ventilator(HRV).The heat exchanger core work for ventilation, recover the heat energy in winter and cold energy in summer, not only save the energy but also give room for fresh air.

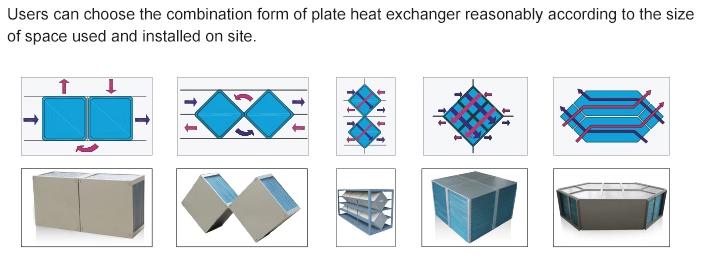

Combination:

Package and Delivery:

Packaging Details: carton or plywood case.

Port: Xiamen port, or as requirement.

Transport Way: by sea, air, train, truck, express etc.

Delivery Time: as below.

| Samples | Mass production | |

| Products Ready: | 7-15 days | To be negotiated |

Product detail pictures:

Related Product Guide:

We also present product or service sourcing and flight consolidation products and services. We have our possess manufacturing facility and sourcing place of work. We can easily supply you with almost every type of product or service connected to our item variety for Wholesale Price Enthalpy Air To Air Counterflow Heat Exchanger - ERD Cross&Counter Flow Heat Exchanger – AIR-ERV , The product will supply to all over the world, such as: Istanbul, Argentina, Frankfurt, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.