Air heat exchangers are critical components in a variety of applications, from heating and cooling systems in residential and commercial buildings to industrial processes such as power generation and manufacturing. These devices work by transferring heat from one air to another air,the two flows are undirect contact with each other. This article will explore how air heat exchangers work and their various applications in different industries.

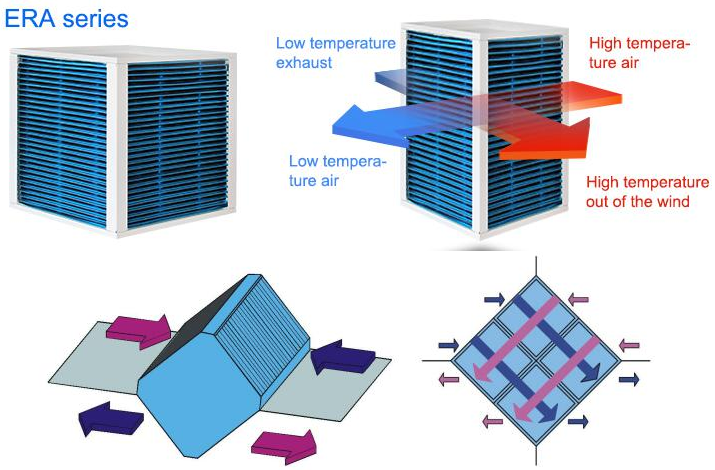

The working principle of air heat exchangers is based on the basic concept of heat transfer. When two fluids of different temperatures come into contact, heat naturally flows from the hotter fluid to the cooler fluid. In the case of an air heat exchanger, one fluid is usually the air that needs to be heated or cooled, and the other fluid is usually a liquid, such as water or refrigerant. The two fluids flow through separate channels in the exchanger, which are separated by solid walls or a series of fins. As the fluids flow past each other, heat is transferred through the walls/fins, creating the desired temperature change.

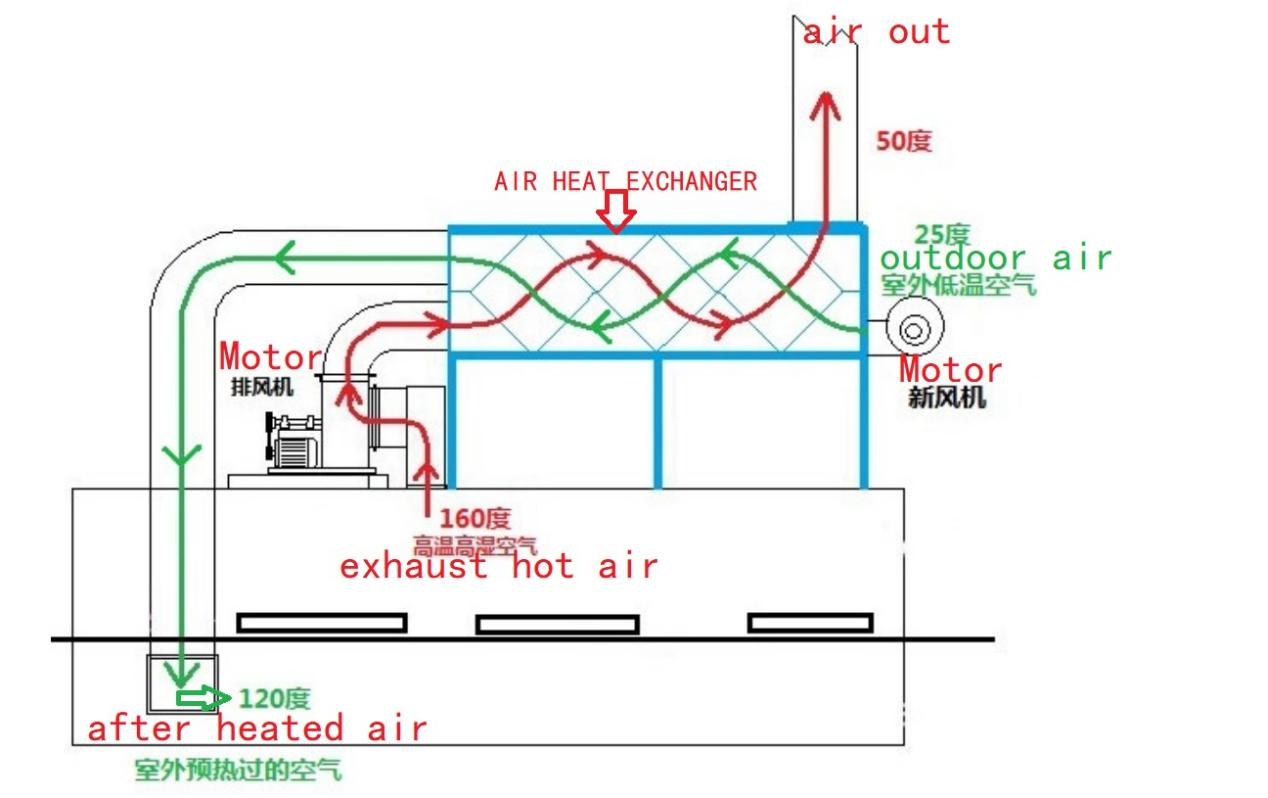

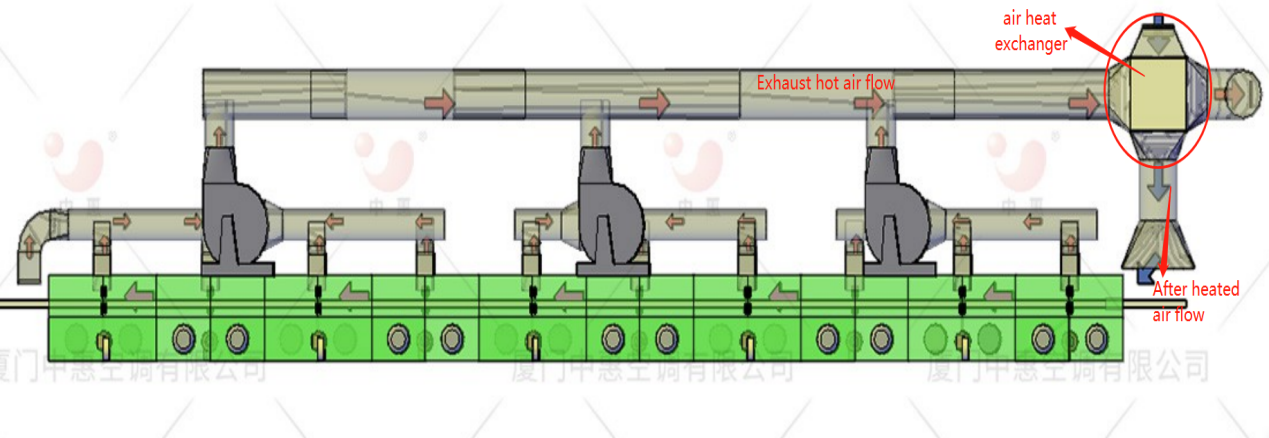

One of the main advantages of air heat exchangers is their efficiency and energy saving potential. By utilizing the heat exchange process, these devices can recover and reuse thermal energy that would otherwise be wasted. For example, in a heating system, the warm air coming out can transfer heat to the cold air coming in, reducing the energy required to reach the desired temperature. Likewise, in industrial applications, air heat exchangers can help improve the overall energy efficiency of processes such as combustion and waste heat recovery.

In residential and commercial HVAC (heating, ventilation and air conditioning) systems, air heat exchangers are often used for heat recovery and ventilation purposes. Also known as air-to-air heat exchangers, these devices are designed to transfer heat between exhaust and incoming airflow, helping to maintain comfortable indoor temperatures while reducing energy costs. Additionally, air heat exchangers play a vital role in ensuring proper ventilation by removing dirty air and introducing fresh air into the building.

In industry, air heat exchangers are used in a wide range of applications, including power plants, chemical processing plants, and manufacturing facilities. For example, in power generation, these devices are used to recover waste heat in flue gases and convert it into useful energy for processes such as preheating boilers or generating electricity. In the chemical industry, air heat exchangers are used in heating and cooling operations, as well as to condense and evaporate various gases. Additionally, during manufacturing processes, air heat exchangers are critical for controlling the temperature of equipment such as ovens, dryers, and heat treatment furnaces.

In conclusion, air heat exchangers are versatile and essential components that play a key role in a variety of applications, playing a key role in energy efficiency, thermal management and process optimization. By understanding their working principles and various applications, engineers and technicians can make informed decisions when selecting and designing air heat exchangers for specific requirements. With the continuous advancement of technology, the development of more efficient and sustainable air heat exchangers will undoubtedly contribute to the improvement of energy conservation and environmental protection.

Post time: Jan-26-2024