The specific function of the heat recovery system of the heat setting machine is to capture and reuse the heat generated during the heat setting process of textiles. Heat setting is a key step in the textile manufacturing process, where heat is applied to synthetic fibers to give them shape and stability. During this process, a large amount of heat is generated, which can be harnessed and reused through a heat recovery system. This not only reduces energy consumption and operating costs, but also minimizes the environmental impact of textile production.

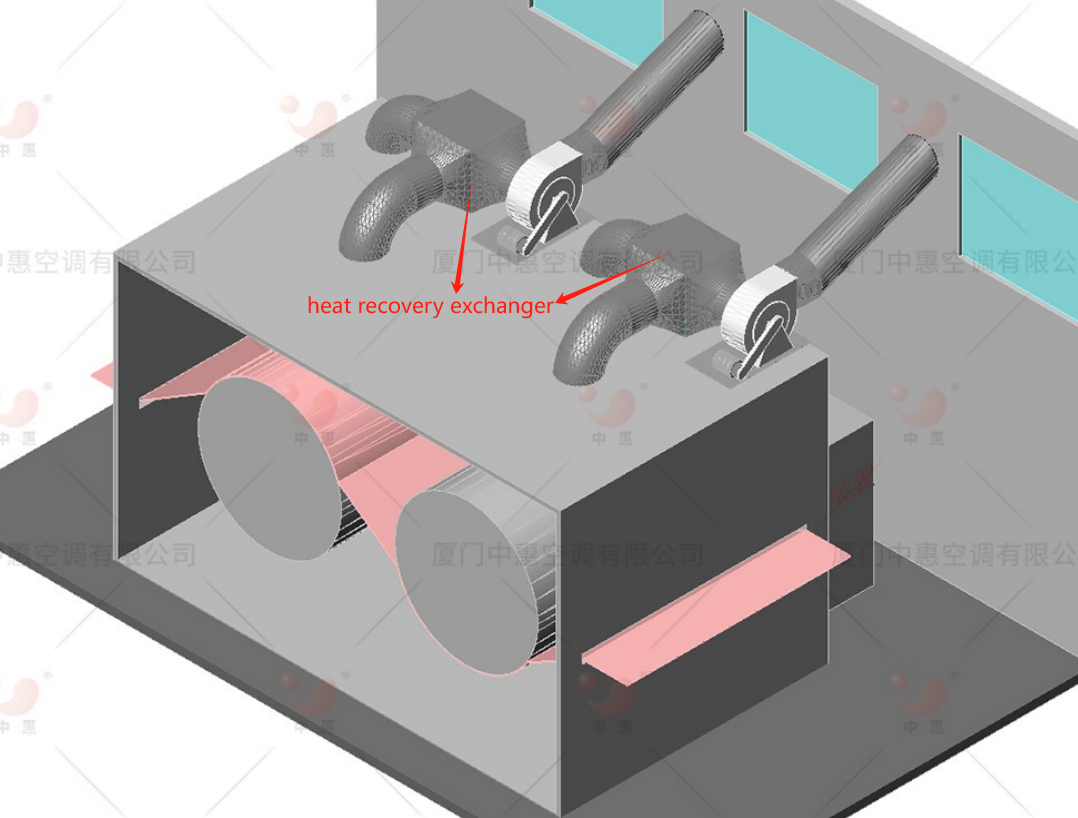

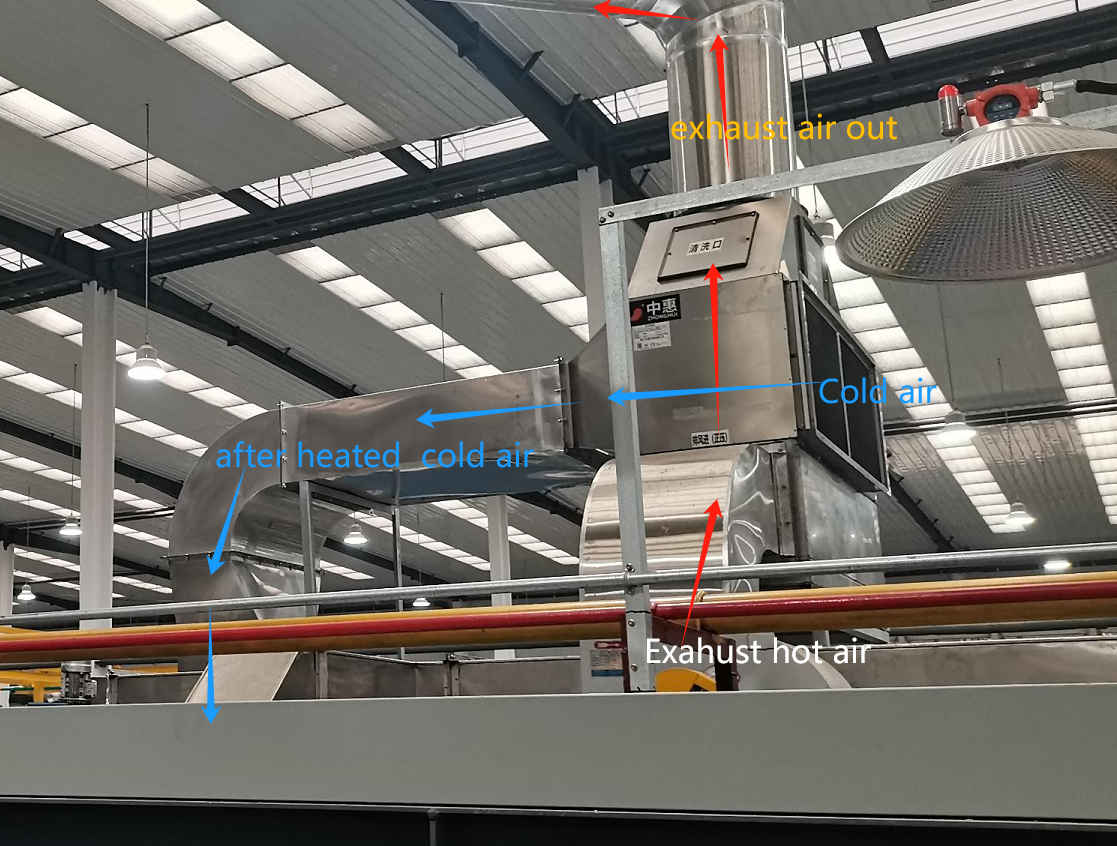

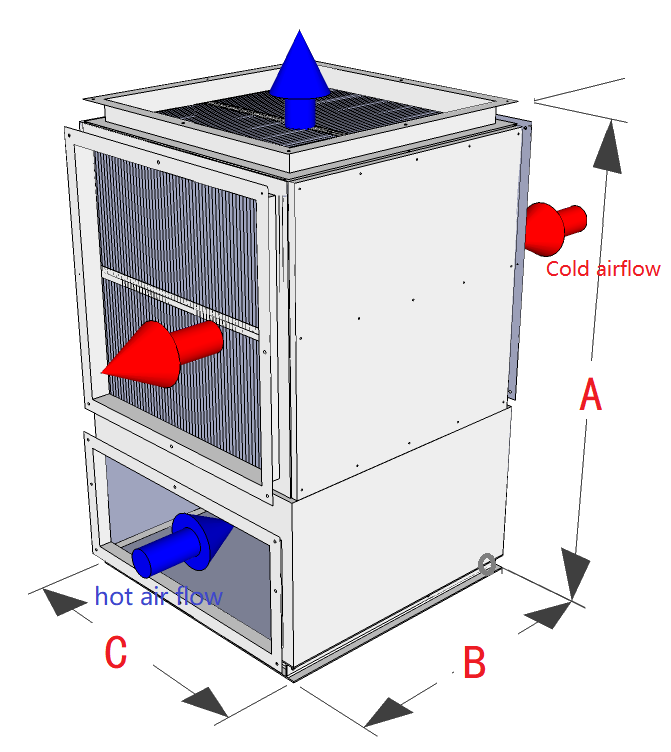

The working principle of the heat recovery system of the heat setting machine is to capture the hot air and exhaust gas generated during the heat setting process. The exhaust hot air pass through a heat exchanger and the heat is transferred to fresh air .This after heated air can be used to preheat incoming air for the heat-setting process, thereby reducing the energy required to reach the desired temperature. By reusing heat that would otherwise be wasted, heat recovery systems significantly increase the overall energy efficiency of the heat setting machine.

In addition to reducing energy consumption and operating costs, thermosetting machine heat recovery systems contribute to a more sustainable and environmentally friendly textile manufacturing process. By reusing the heat generated during the heat setting process, the system helps reduce greenhouse gas emissions and minimize reliance on non-renewable energy sources. This is in line with the textile industry’s growing focus on sustainability and environmental responsibility, making the integration of heat recovery systems a valuable investment for textile manufacturers looking to improve their environmental footprint while reducing operating expenses.

Post time: Aug-24-2024