Lowest Price for Air Purification Heat Recovery Ventilator - ERA Cross Flow Heat Exchanger – AIR-ERV

Lowest Price for Air Purification Heat Recovery Ventilator - ERA Cross Flow Heat Exchanger – AIR-ERV Detail:

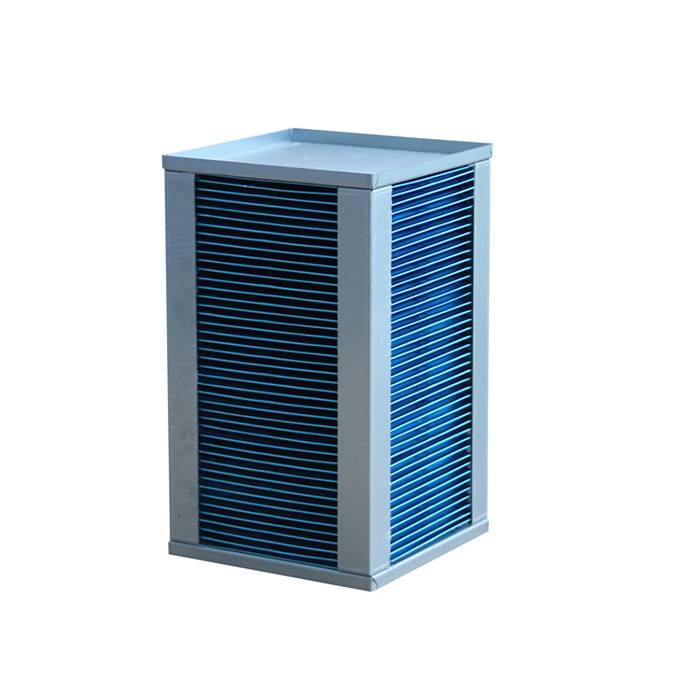

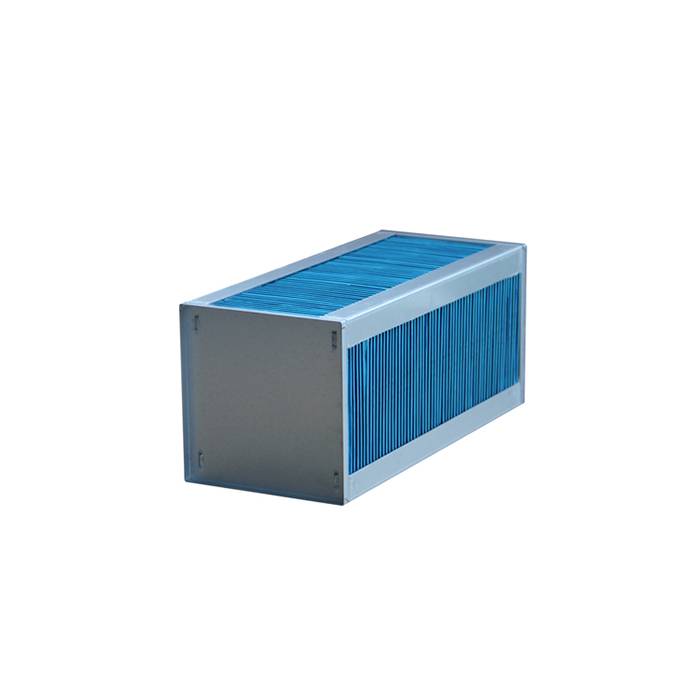

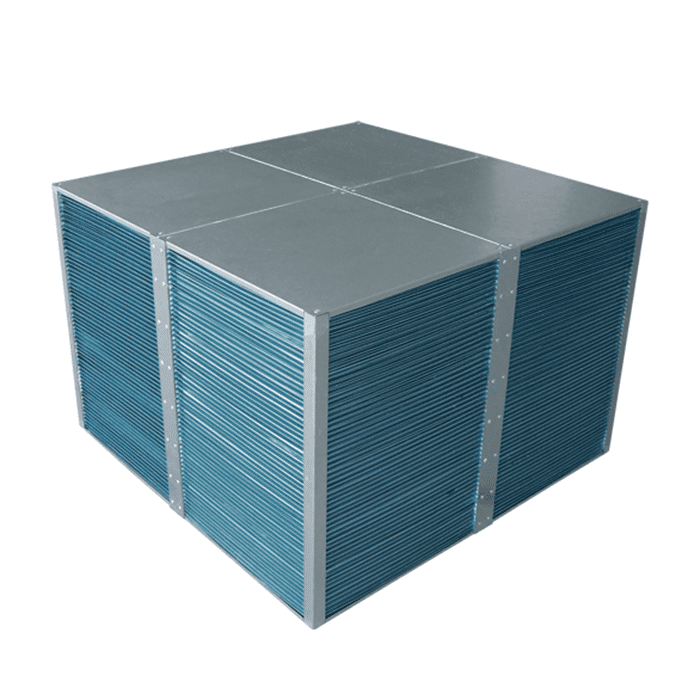

ERA Cross Flow Heat Exchanger Core

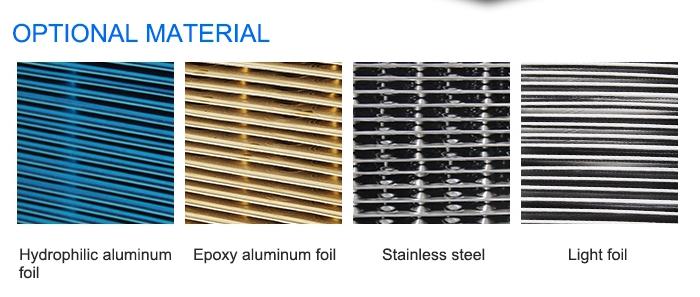

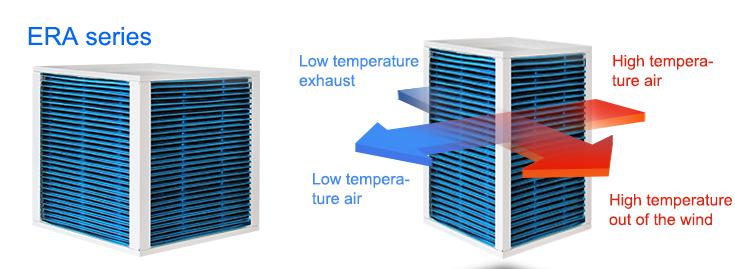

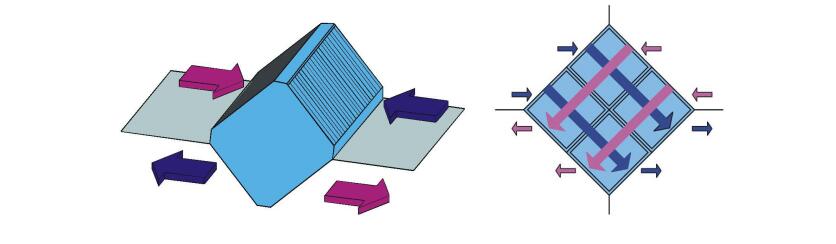

Cross flow heat exchanger core is made of antiseptic hydrophilic/epoxy coating aluminum foil and galvanized sheet cover. The air is forced to crossover through the heat exchanger core, two air streams never come into direct contact, avoid the transfer of any smell and moisture.

It is usually being used for recovering energy at residential, commercial and wind-power industry ventilation systems.

Feature:

*Adopt antiseptic hydrophilic aluminium foil, resistant to corrosion, with long service life.

*Apply to special occasions of epoxy resin aluminum foil, corrosion resistance stronger.

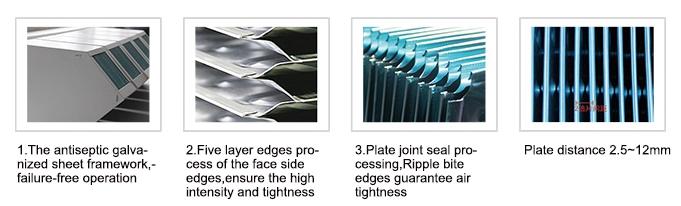

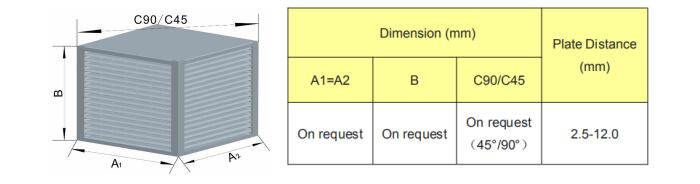

*Many size heat exchanger core (plate distance 2.5-12mm)for your choice.

*Module structure, any sine can be praided, no running components, low maintenance cost.

*Compact structure, small volume, suitable for various occasions.

Production Technology:

1.The surface of heat exchanger core was processed with heat transfer enhancement techniques, increased the 10% heat transfer area.

2.Convex and concave air channel, ensure the strength and tightness of heat exchanger core, could bear high pressure.

3.Cross air channel, double folding process of the face side edges, which is equal to 5 times material thickness, ensure the high intensity and tightness.

4. All joints are air-proofed by air-proof glue, ensured that the heat exchanger core has excellent air tightness.

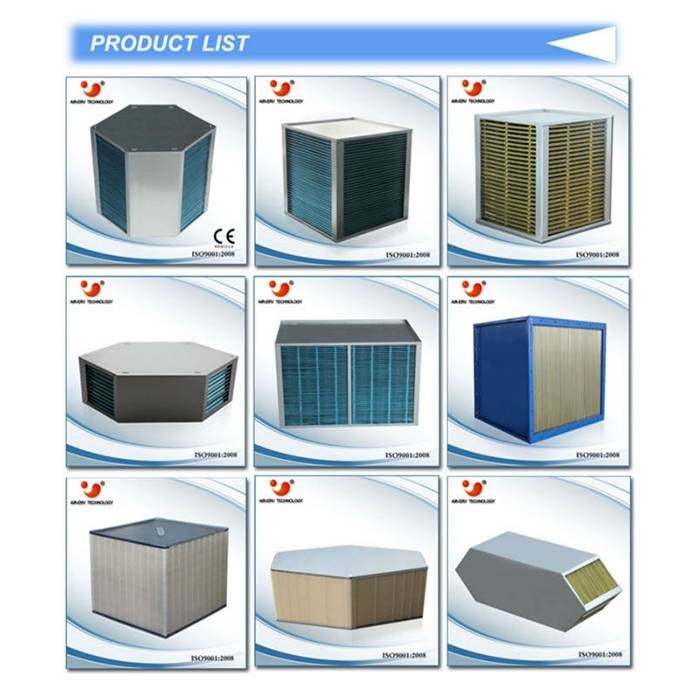

Model Range:

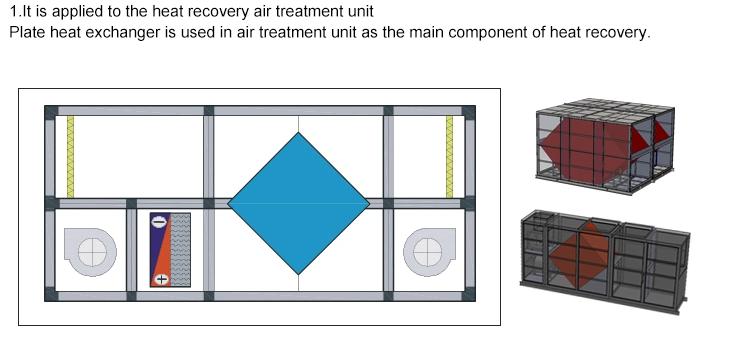

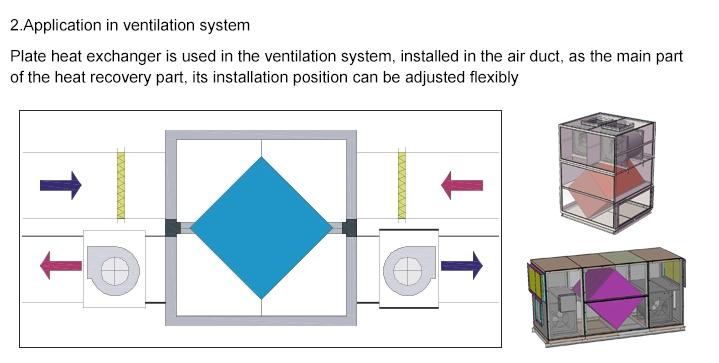

Application:

The ERA heat exchanger core is the major part of heat recovery ventilator(HRV), for air volumes up to 30,000 m3/h, include the household and commercial ventilation. The heat exchanger core recover the heat energy in winter and cold energy in summer, so as to save the energy and give room for fresh air.

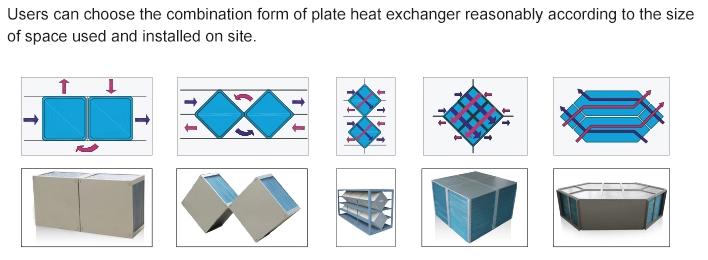

Combination:

Package and Delivery:

Packaging Details: carton or plywood case.

Port: Xiamen port, or as requirement.

Transport Way: by sea, air, train, truck, express etc.

Delivery Time: as below.

| Samples | Mass production | |

| Products Ready: | 7-15 days | To be negotiated |

Product detail pictures:

Related Product Guide:

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Lowest Price for Air Purification Heat Recovery Ventilator - ERA Cross Flow Heat Exchanger – AIR-ERV , The product will supply to all over the world, such as: Kuwait, Sudan, Macedonia, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!